1555F Series enclosures have several innovative features that provide excellent functionality

Introduction to Gas Sensors: Construction Types and Working

A Typical human nose has 400 types of scent receptors enabling us to smell about 1 trillion different odours. But still many of us do not have the capacity to identify the type or concentration of gas present in our atmosphere. This is where Sensors comes in, there are many types of sensors to measure different parameters and a Gas sensor is one which comes handy in applications where we have to detect the variation in the concentration of toxic gases in order to maintain the system safe and avoid/caution any unexpected threats. There are various gas sensors to detect gases like oxygen, Carbon Dioxide, Nitrogen, methane etc. They can also be commonly found in devices that are used to detect the leakage of the harmful gases, monitor the air quality in industries and offices etc.

In this article, we will learn more about gas sensors, their construction, types, working and how they can be used to measure the required type and concentration of Gas in our atmosphere. There are many types of Gas sensors but the MQ type gas sensors are commonly used and widely popular so will focus more on these types of sensors for this article.

Introduction to Gas Sensor

A gas sensor is a device which detects the presence or concentration of gases in the atmosphere. Based on the concentration of the gas the sensor produces a corresponding potential difference by changing the resistance of the material inside the sensor, which can be measured as output voltage. Based on this voltage value the type and concentration of the gas can be estimated.

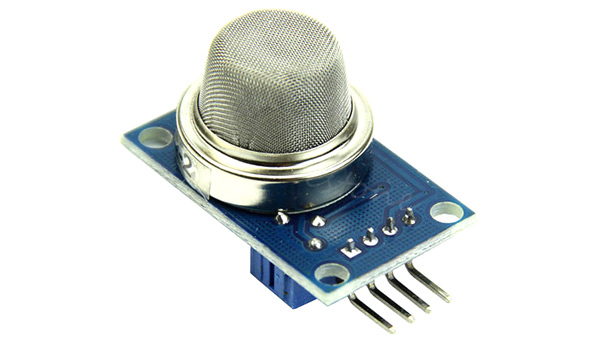

The type of gas the sensor could detect depends on the sensing material present inside the sensor. Normally these sensors are available as modules with comparators as shown above. These comparators can be set for a particular threshold value of gas concentration. When the concentration of the gas exceeds this threshold the digital pin goes high. The analog pin can be used to measure the concentration of the gas.

Different Types of Gas sensors

Gas sensors are typically classified into various types based on the type of the sensing element it is built with. Below is the classification of the various types of gas sensors based on the sensing element that are generally used in various applications:

- Metal Oxide based gas Sensor.

- Optical gas Sensor.

- Electrochemical gas Sensor.

- Capacitance-based gas Sensor.

- Calorimetric gas Sensor.

- Acoustic based gas Sensor.

Gas Sensor Construction

Of all the above-listed types, the most commonly used gas sensor is the Metal oxide semiconductor based gas sensor. All Gas sensors will consist of a sensing element which comprises of the following parts.

- Gas sensing layer

- Heater Coil

- Electrode line

- Tubular ceramic

- Electrode

The below image illustrates the parts present in a metal oxide gas sensor

The purpose of each of these elements is as below:

Gas sensing layer: It is the main component in the sensor which can be used to sense the variation in the concentration of the gases and generate the change in electrical resistance. The gas sensing layer is basically a chemiresistor which changes its resistance value based on the

The concentration of particular gas in the environment. Here the sensing element is made up of a Tin Dioxide (SnO2) which is, in general, has excess electrons (donor element). So whenever toxic gases are being detected the resistance of the element changes and the current flown through it varies which represents the change in concentration of the gases.

Heater coil: The purpose of the heater coil is to burn-in the sensing element so that the sensitivity and efficiency of the sensing element increases. It is made of Nickel-Chromium which has a high melting point so that it can stay heated up without getting melted.

Electrode line: As the sensing element produces a very small current when the gas is detected it is more important to maintain the efficiency of carrying those small currents. So Platinum wires come into play where it helps in moving the electrons efficiently.

Electrode: It is a junction where the output of the sensing layer is connected to the Electrode line. So that the output current can flow to the required terminal. An electrode here is made of Gold (Au –Aurum) which is a very good conductor.

Tubular ceramic: In between the Heater coil and Gas sensing layer, the tubular ceramic exists which is made of Aluminum oxide (Al2O3). As it has high melting point, it helps in maintaining the burn-in (preheating) of the sensing layer which gives the high sensitivity for the sensing layer to get efficient output current.

Mesh over the sensing element: In order to protect the sensing elements and the setup, a metal mesh is used over it, which is also used to avoid/hold the dust particles entering into the mesh and prevent damaging the gas sensing layer from corrosive particles.

Gas Sensor Working

The ability of a Gas sensor to detect gases depends on the chemiresister to conduct current. The most commonly used chemiresistor is Tin Dioxide (SnO2) which is an n-type semiconductor that has free electrons (also called as donor). Normally the atmosphere will contain more oxygen than combustible gases. The oxygen particles attract the free electrons present in SnO2 which pushes them to the surface of the SnO2. As there are no free electrons available output current will be zero. The below gif shown the oxygen molecules (blue color) attracting the free electrons (black color) inside the SnO2 and preventing it from having free electrons to conduct current.

When the sensor is placed in the toxic or combustible gases environment, this reducing gas (orange color) reacts with the adsorbed oxygen particles and breaks the chemical bond between oxygen and free electrons thus releasing the free electrons. As the free electrons are back to its initial position they can now conduct current, this conduction will be proportional the amount of free electrons available in SnO2, if the gas is highly toxic more free electrons will be available.

How to use a Gas sensor?

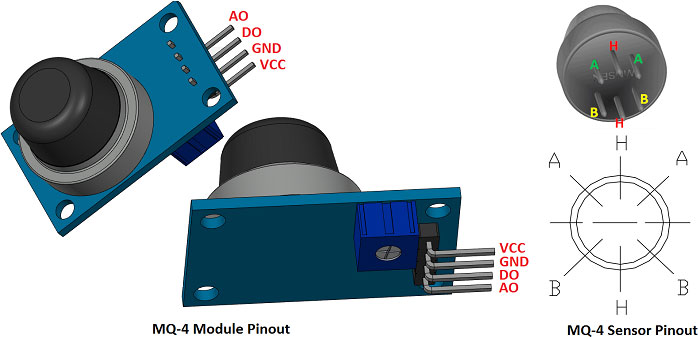

A basic gas sensor has 6 terminals in which 4 terminals (A, A, B, B) acts input or output and the remaining 2 terminals (H, H) are for heating the coil. Of these 4 terminals, 2 terminals from each side can be used as either input or output (these terminals are reversible as shown in the circuit diagram) and vice versa.

These sensors are normally available as modules (shown right), these modules consist of the gas sensor and a comparator IC. Now let’s see the pin description of the gas sensor module which we will generally use with an Arduino. The gas sensor module basically consists of 4 terminals

- Vcc – Power supply

- GND – Power supply

- Digital output – This pin gives an output either in logical high or logical low (0 or 1) that means it displays the presence of any toxic or combustible gases near the sensor.

- Analog output – This pin gives an output continuous in voltage which varies based on the concentration of gas that is applied to the gas sensor.

As discussed earlier the output of a gas sensor alone will be very small (in mV) so an external circuit has to be used in order to get a digital high low output from the sensor. For this purpose, a comparator (LM393), adjustable potentiometer, some resistors and capacitors are used.

The purpose of LM393 is to get the output from the sensor, compare it with a reference voltage and display whether the output is logically high or not. Whereas the purpose of the potentiometer is to set the required threshold value of the gas above which the digital output pin should go high.

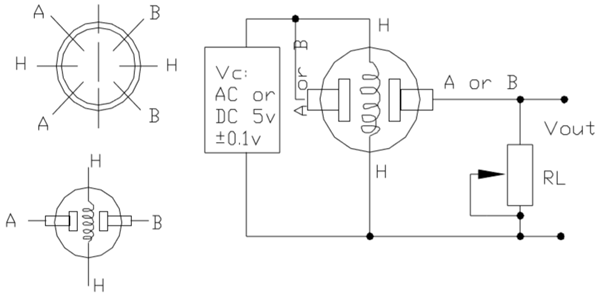

The below diagram shows the basic circuit diagram of a gas sensor in a gas sensor module

Here A and B are the input and output terminals (these are reversible - means any of the paired terminals can be used as input or output) and H is the Heater coil terminal. The purpose of the variable resistor is to adjust the output voltage and to maintain high sensitivity.

If no input voltage is applied to the heater coil, then the output current will be very less (which is negligible or approximately 0). When sufficient voltage is applied to the input terminal and heater coil, the sensing layer wakes up and is ready to sense any combustible gases nearby it. Initially let’s assume that there is no toxic gas near the sensor, so the resistance of the layer doesn’t change and the output current and voltage are also unchanged and are negligible (approximately 0).

Now let’s assume that there is some toxic gas nearby. As the heater coil is pre-heated it is now easy to detect any combustible gases. When the sensing layer interacts with the gases, the resistance of the material varies and the current flowing through the circuit also varies. This change in variation can be then observed at the load resistance (RL).

The value of load resistance (RL) can be anywhere from 10KΩ to 47KΩ. The exact value of the load resistance can be selected by calibrating with the known concentration of the gas. If low load resistance is selected then the circuit has less sensitivity and if high load resistance is selected then the circuit has high sensitivity.

List of Different Types of Gas Sensors and What Gases They Sense

|

Sensor Name |

Gas to measure |

|

Methane, Butane, LPG, Smoke |

|

|

MQ-3 |

Alcohol, Ethanol, Smoke |

|

Methane, CNG Gas |

|

|

MQ-5 |

Natural gas, LPG |

|

LPG, butane |

|

|

MQ-7 |

Carbon Monoxide |

|

MQ-8 |

Hydrogen Gas |

|

MQ-9 |

Carbon Monoxide, flammable gasses |

|

MQ131 |

Ozone |

|

Air Quality |

|

|

MQ136 |

Hydrogen Sulphide gas |

|

Ammonia |

|

|

MQ138 |

Benzene, Toluene, Alcohol, Propane, Formaldehyde gas, Hydrogen |

|

MQ214 |

Methane, Natural Gas |

|

MQ216 |

Natural gas, Coal Gas |

|

MQ303A |

Alcohol, Ethanol, smoke |

|

MQ306A |

LPG, butane |

|

MQ307A |

Carbon Monoxide |

|

MQ309A |

Carbon Monoxide, flammable gas |

Applications of Gas Sensors

- Used in industries to monitor the concentration of the toxic gases.

- Used in households to detect an emergency incidents.

- Used at oil rig locations to monitor the concentration of the gases those are released.

- Used at hotels to avoid customers from smoking.

- Used in air quality check at offices.

- Used in air conditioners to monitor the CO2 levels.

- Used in detecting fire.

- Used to check concentration of gases in mines.

- Breath analyzer.