1555F Series enclosures have several innovative features that provide excellent functionality

Different Types of Sensors and Sensing Technologies

What is a Sensor?

Sensor is a device that has the capability to detect change in its surrounding environment and provides output in the form of analog or digital signal, which is then either displayed or can be used by a closed loop system for process control. For better understanding, we can say that sensor is a device that can see, hear, feel, smell, and taste its surrounding and probably do it better than me or you (obviously it depends on the make and quality of the sensor). Sensors are usually connected to a transmitter because the output of sensor needs to be conditioned or amplified, because the output is very small. Hence, a sensor requires other equipment for us to utilize the data, and most often than not we call the whole package as a sensor. In this article, I will be writing about some common sensors available in the market, I will be giving you brief information about those sensors and will also tell you it’s application in real world.

Difference between Sensor and Transducer

Before diving into the different types of sensors, the first thing that we should know is the difference between the sensors and the transducers.

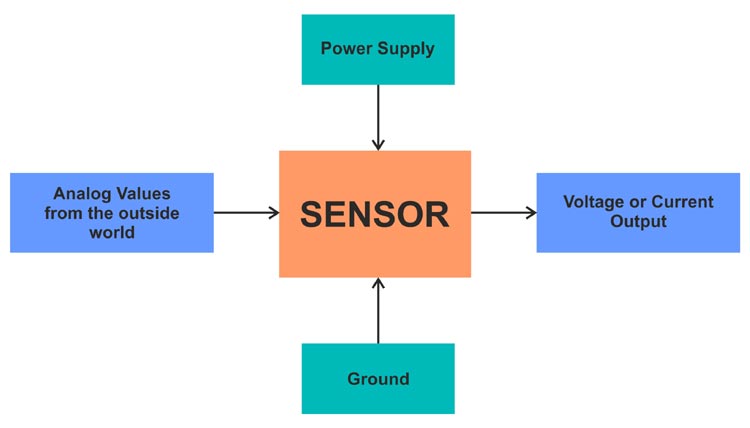

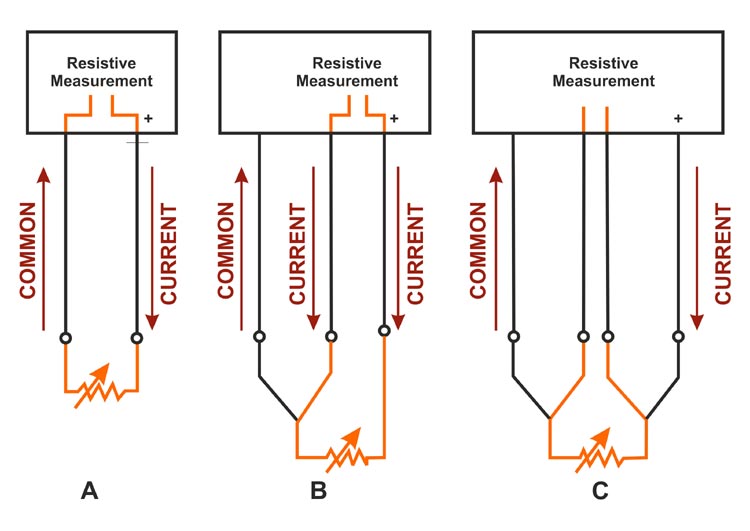

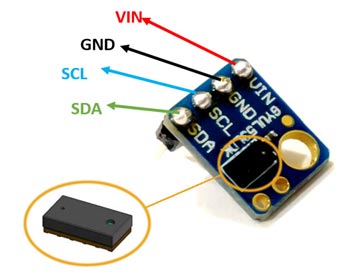

Sensor is a module or chip that observes the changes happening in the physical world and sends the feedback to the microcontroller or microprocessor. As shown in the figure above, excitation (Power supply) and Grounding must be provided to the sensor for the proper working.

Transducer also observes the changes happening in the physical world, but unlike a sensor, it doesn’t requires power, it measures the change and convert it into the form of voltage output. There are 2 kind of transducers, input transducers which takes energy or measurement in a form and convert it into electricity, for e.g. a microphone. Whereas, an output transducer takes electrical energy and convert it into other form of energy, for e.g. a speaker.

Classification of Sensors

In process control, there are two types of sensors as mentioned below:

Active and Passive Sensors

Passive sensor requires an external source of power to work. For e.g. a thermoresistor, Light resistor, strain gauge, etc. While an active sensor doesn’t require any external source of power. For e.g. a Piezo electric, thermocouple, etc.

Analog and Digital Sensors

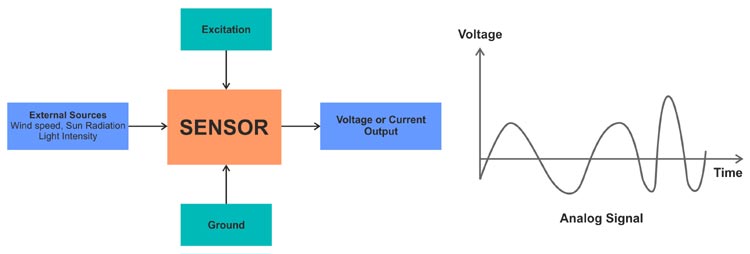

The analog sensor gives output in the form of analog output when they detect change in external parameter (wind speed, solar radiation, light intensity, etc.).

An analog sensor with output range of 0 to 5V can give the output anywhere between 0V and 5V.

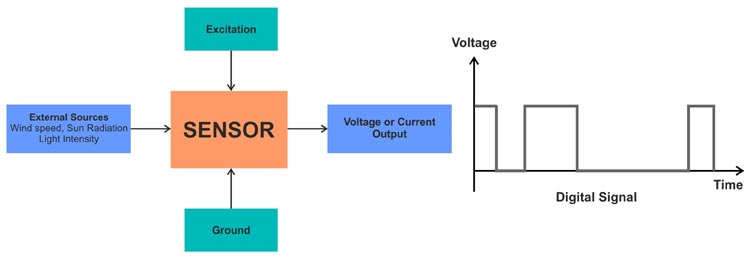

Unlike analog sensor, Digital Sensor produce discrete values (0 and 1’s). Discrete values often called digital (binary) signals in digital communication.

Logic High is treated as “1” whereas the Logic Low is indicated by “0”.

Different Types of Sensors

In today’s time, there are multiple sensors for detecting different parameter and measuring different characteristics of physical world. Many of the sensors can be utilized in detecting data in different scenario. For example, an ultrasonic sensor can be used for detecting distance, speed, temperature, etc. just by using different calculation from its acquired data. Therefore, sensors can be classified into different parameters. Sensor’s can be classified based on the physical parameter it senses, they can also be categorized based on the applications, or by the industry they are being used. So, in this article, I’ve classified the sensors based on their most prominent usages.

Some common types of Sensors are:

- Temperature Sensors & Thermocouple Sensors

- Proximity Sensor

- Ultrasonic sensor

- Pressure Sensor

- Hall Effect Sensor

- Load cell

- Light Sensor

- Color Sensor

- Touch Sensor

- Tilt Sensor

- PIR Motion Detector & Vibration Sensor

- Accelerometers & Gyroscope Sensor

- Metal detector, Water Flow & Heartbeat Sensor

- Flow and Level Sensor

- Gas and Alcohol Sensor

- Humidity and Soil Moisture sensor

Temperature Sensor

Temperature sensors are used for measuring the temperature of any object or medium. Temperature is a fundamental measurement of thermal energy which has a SI unit in Kelvin. It is one of the most widely used sensor. The majority of these are contact sensors while infrared and ultrasonic temperature sensors are contactless sensors.

Temperature Sensor types

Temperature sensor come in both analog and digital type. The most commonly used temperature sensors are thermocouples, thermistors, and RTDs.

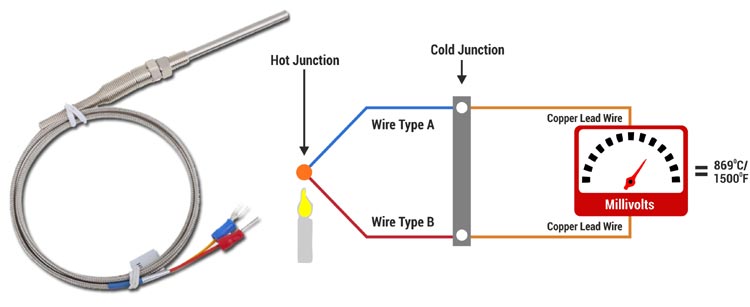

Thermocouples:

These are the most commonly used type of temperature sensor. They are made by joining two dissimilar metal wires together and works on the principle of Seebeck Effect. Thermocouples are preferred because they are self-powered and require no excitation while working over a wide temperature range.

Usage - These sensors are used in industrial, automotive, and consumer applications.

RTDs:

The resistance temperature detector also known as RTDs work on the principle that the resistance of metals is affected by its temperature. RTDs are commonly made up of platinum, nickel, or copper wires, due to their positive temperature coefficient, i.e., the rise in temperature results in an increased resistance – the change of resistance is then used to detect and measure temperature changes.

Thermistors

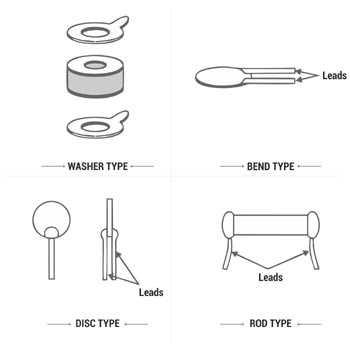

Similar to RTD, thermistor also measures the change in resistance to measure temperature, but unlike RTD thermistors are made up of ceramic or polymer materials. Mostly thermistors are cheaper but are also less accurate than RTDs. Most thermistors are available in two wire configurations, NTC (Negative Temperature Coefficient) and PTC (Positive temperature coefficient). The NTC have an inverse relationship with the temperature, i.e., with increase in temperature the resistance increases and with decrease in temperature resistance increases whereas in the PTC the resistance increases with increase in temperature and vice versa. PTC are more commonly used as fuse. Some common thermistors are shown in the image below.

Some other kind of temperature sensors are:

- Thermometers

- Vibrating Wire Temperature Sensors

- Infrared temperature sensor

- Ultrasonic temperature sensor

Temperature Sensors Application

Thermal sensors are widely used for temperature measurement in Medical applications, power electronic circuits, battery packs, computers, aerospace applications, automotive applications, environmental monitoring, etc.

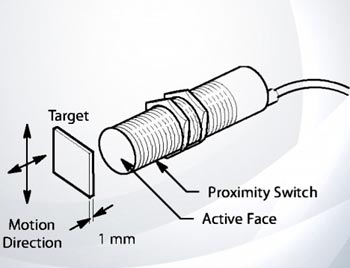

Proximity Sensors

Proximity sensors are sensing devices capable of detecting the presence of object without physical contact. These are among the most commonly used sensors. There are different kind of proximity sensors depending on the physical quantity they measure.

Types of Proximity Sensors

- Inductive proximity sensors

- Magnetic proximity sensors

- Capacitive proximity sensors

- Photoelectric proximity sensors

- Ultrasonic proximity sensors

Proximity Sensors Application

It is most commonly used in industries to measure the close proximity of any mechanical parts, in mobiles, proximity sensors are used for detection face during calls. They are used in safety system and in automotive, aerospace industry etc.

Position Sensors

Position sensors are devices that can detect the movement of an object or determine its relative position measured from an established reference point. These types of sensors can also be used to detect the presence of an object or its absence. Position sensors are sometimes confused with proximity sensors. Although both these sensors are very similar to each other, in fact all the proximity sensors can be considered as a position sensor, but the main difference is that position sensor gives the exact position of an object, whereas the proximity sensor only tells about the presence or absence of an object in an area.

There are several sensor types that serve similar purposes to position sensors and which are worthy of mentioning. Motion sensors detect the movement of an object and can be used to trigger action such as turn on light and fan automatically or activating a security camera. Proximity sensors as well can detect that an object has come within range of the sensor. Both sensors, therefore, might be considered as a specialized form of position sensors.

Position sensors are capable not only to detect any object but also to measure and record the position and therefore involve the use of a feedback signal that contains positional information.

Different types of Positional Sensors are

- Potentiometric Position Sensors (resistance-based)

- Inductive Position Sensors

- Eddy Current-Based Position Sensors

- Capacitive Position Sensors

- Magnetostrictive Position Sensors

- Hall Effect-Based Magnetic Position Sensors

- Fiber-Optic Position Sensors

- Optical Position Sensors

- Ultrasonic Position Sensors

The two most common types of position sensors are Hall effect and ultrasonic sensor.

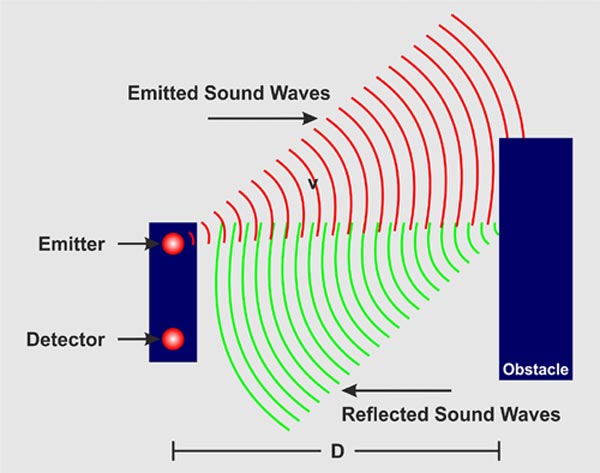

Ultrasonic Sensor

This sensor uses ultrasonic waves to detect any object in its path. It has a transmitter and a receiver which are made by piezo electric crystals. The transmitter produces the ultrasonic waves and the wave hits the object and returns back to the same path which is detected by the ultrasonic receiver. The ultrasonic sensor utilizes the time of flight (TOF) technique to measure distance of the object. Ultrasonic waves travel faster than the speed of audible sound (i.e. the sound that humans can hear).

In order to calculate the distance between the sensor and the object, the sensor measures the time it takes between the emission of the sound by the transmitter to its contact with the receiver. The formula for this calculation is

D = ½ T x C

here, D is the distance between transmitter and the object, T is the time, and C is the speed of sound ~ 343 meters/second.

The image below shows a HC-SR04, it is one of the most widely used ultrasonic sensor by the hobbyists. It has both transmitter and receiver in a single module.

Application

These sensors are mostly used to detect object, measure distance and can also be used for measuring temperature, pressure, fault in structure or material, etc.

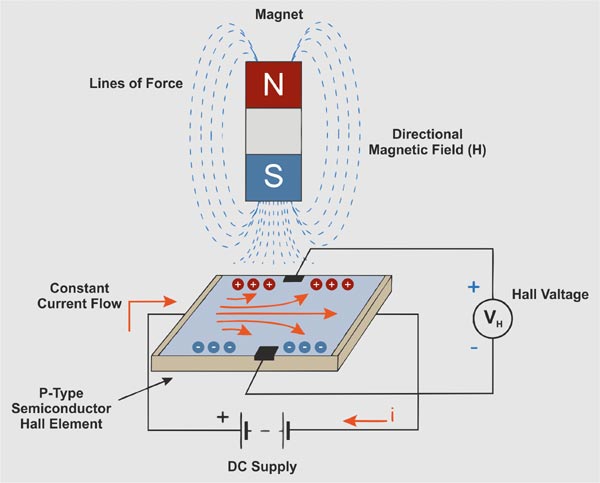

Hall Effect Sensors

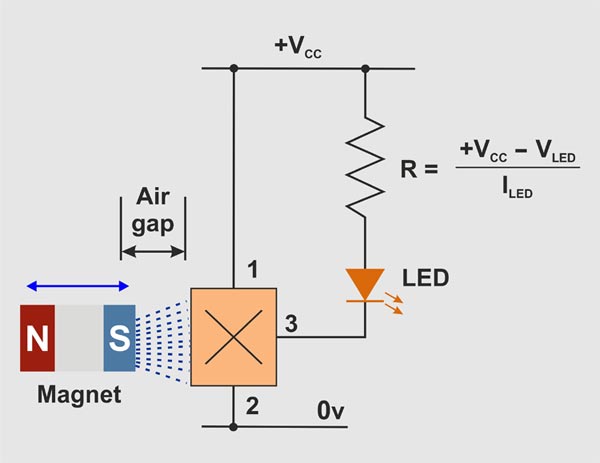

Hall Effect Sensors senses the external magnetic field. The output signal from a Hall effect sensor is the function of magnetic field density around the device. When the magnetic flux density around the sensor exceeds a certain pre-set threshold, the sensor detects it and generates an output voltage called the Hall Voltage, VH.. The hall effect sensor has various application, but is mostly used in the position detection.

Positional Detector

Positional detectors are sensors which are used to detect the position of any object, they can be made using distance sensors such as ultrasonic sensors or by using proximity sensors such as hall effect sensors etc.

Some other kind of positional detectors are:

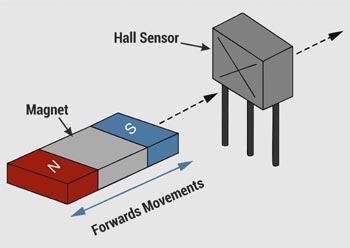

1. Head-on Detection

As its name implies, “head-on detection” requires that the magnetic field is perpendicular to the hall effect sensing device and that for detection, it approaches the sensor straight on towards the active face. A sort of “head-on” approach

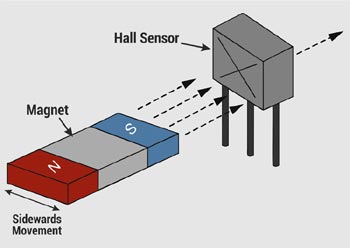

2. Sideways Detection

The second sensing configuration is “sideways detection”. This requires moving the magnet across the face of the Hall effect element in a sideways motion.

This head-on positional detector will be “OFF” when there is no magnetic field present, (0 gauss). When the permanent magnets south pole (positive gauss) is moved perpendicular towards the active area of the Hall effect sensor the device turns “ON” and lights the LED. Once switched “ON” the Hall effect sensor stays “ON”.

Positional Detectors Application

Positional detectors are widely used in assembly lines to measure position and send feedback to the control system, its also used in engines to detect position of crankshaft for proper combustion.

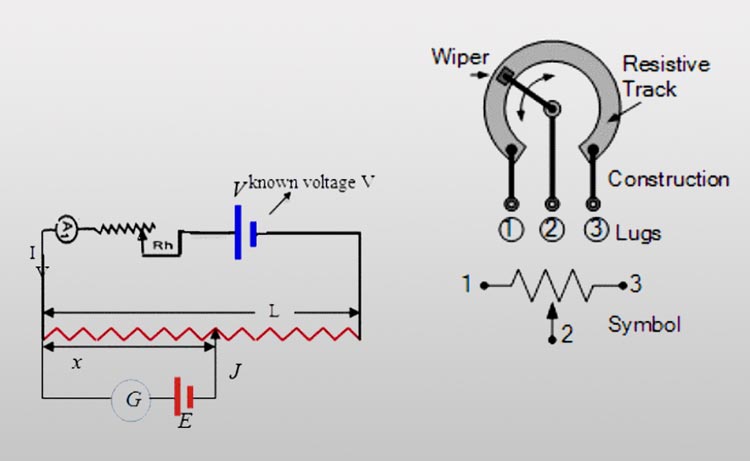

Potentiometer Sensors

It is a contact type sensor which measures the distance or displacement of an object in linear or rotary motion respectively and provides an electrical output. It is of 3 types used for detecting different position of movement. It uses the same principal as a potentiometer used for changing the flow of current in an electric circuit.

Inductive Position Sensor

Inductive position sensors use the physical principles of induction in a wire loop and eddy currents to detect the position of a solid metallic structure that is sliding or rotating above a set of coils consisting of one transmitter coil and two receiver coils.

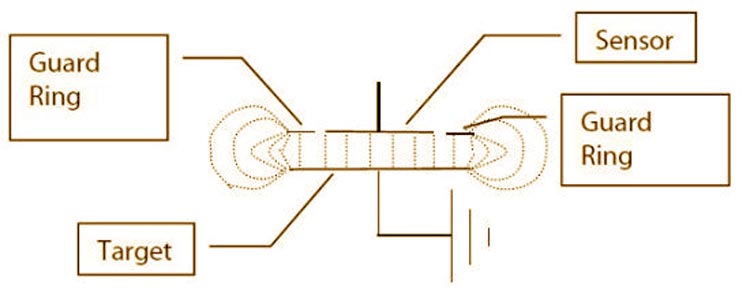

Capacitive Sensor

Capacitive sensors are designed for non-contact measurement of displacement, distance and position, as well as for thickness measurement. Due to their high signal stability and resolution, capacitive displacement sensors are applied in laboratories and industrial measurement tasks.

Position Sensors Application

Position sensors are widely used for machine Tools, robotics, motion systems, material handling, hydraulic control, steering, braking, etc.

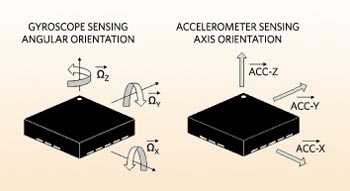

Accelerometers & Gyroscope Sensor

The accelerometer sensor is used to measure the acceleration of a body in any direction while the gyroscope measures rotational velocity or rate of change of the angular position over time, along the X, Y and Z axis. These sensors are used in combination to detect the velocity of an object. A commonly used gyroscope with Arduino is MPU6050 module.

Gyroscope and Accelerometer Sensor Applications

Some of the common application of these sensors are optical Image stabilization used in camera lens, Gesture-Based Control, Navigation, movement detection in mobile phones and other devices, etc.

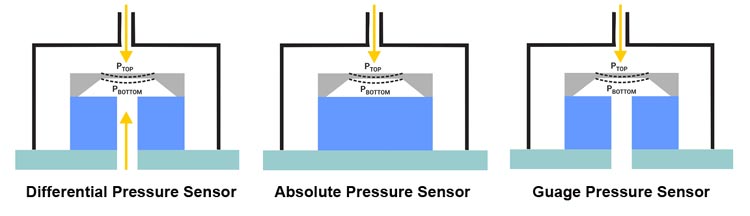

Pressure Sensor

These sensors are used to measure the force exerted on a body or in an environment due to solid, liquid or gaseous object. Pressure = Mass/Unit area. Similar to pressure sensor there are pressure gauges. Pressure gauges by their design provide a direct output reading of a pressure value referred to as gauge pressure. Pressure sensors can be classified into absolute pressure, gauge pressure and differential pressure. Gauge pressure is measured relative to the atmospheric pressure whereas the absolute pressure is measured relative to a vacuum while the differential pressure is measurement of pressure difference between two points.

The above image shows a BMP085, a commonly used barometric pressure sensor from Bosch.

Different type of Pressure measurement are:

- Differential Pressure

- Absolute Pressure

- Guage Pressure

Types of Pressure Sensor

- Potentiometric pressure sensors

- Inductive pressure sensors

- Capacitive pressure sensors

- Piezoelectric pressure sensors

- Strain gauge pressure sensors

Pressure Sensor Applications

Pressure sensors are used to measure pressure exerted on any object or at any point, it can also be used to indirectly measure other variables such as fluid/gas flow, speed, water level, and altitude

Vision and Imaging Sensors/Detectors

As the name suggests, vision and imaging sensors and detectors detect the presence of any object or color within it’s field of view. The detected input is converted into a digital image for display. The sensor module usually have a camera, lights and controller in it. These sensors are used in manufacturing plants and assembly lines to detect any fault in manufacturing process by sensing presence, positioning and abnormality, also they are used in present day cars to ease reversing of vehicle for the driver.

Light Sensor

Light sensors also known as Photoelectric Devices or Photo Sensors converts light energy (photons) into electronic signal (electrons). Photoelectric sensors use light to detect the presence or absence of an object. It emits a light beam (visible or infrared) from its light-emitting element. A reflective-type photoelectric sensor is used to detect the light beam reflected from the target. A beam of light is emitted from the light emitting element and is received by the light receiving element. Both the light emitting and light receiving elements are contained in a single housing. The sensor receives the light reflected from the target. Some different types of light sensors are shown in the image below:

Most common type of light sensors used are Phototransistors, photoresistors, and photodiodes.

A Photoresistor, more commonly known as LDR are resistors whose resistance is dependent on the intensity of light. The resistance is inversely proportional to the intensity of the light, i.e. the resistance is higher in a dark room compared to resistance of LDR in a bright room.

A Phototransistor is an electronic switching and current amplification component which relies on exposure to light to operate, in easier words, phototransistors are a type of transistors that convert light energy into electrical energy, the output is depended on the light intensity.

A Photodiode is a semiconducting device which generates electric current when light falls into it. The main difference between photodiode and photoresistor is that phototransistor only produces current while a photo resistor or Light dependent resistor’s resistance is depended on the intensity of light falling on it.

Light Sensor Application

Light sensor are used in security system, ambient light detection, object detection and have application in Industries, automobiles, military and almost are extensively used by mostly all in everyday lives.

LIDAR Sensor

Light Detection and Ranging also known as LIDAR is a common technique of measuring distance. It works by emitting light which hits an object in it’s path and travels back on its original path which is then detected by the receiver, giving an exact measurement of the distance. The below pic shows a VL53L0X – Lidar sensor, which was also used in the iphone 7 for 3D imaging.

Applications of Lidar Sensor

LIDAR is widely used in camera autofocus to enhance in the camera performance in low light or fast-moving objects conditions, it is also used as a proximity sensor in many phones. LIDAR also finds its application in advance usage in oceanography, terrain modeling of Earth’s surface, Automobile and Aerospace industry, etc.

PIR Sensor

The passive infrared sensor more commonly called as PIR sensor detects the Infrared light radiating from a body. It use a pair of pyroelectric sensors to detect heat energy in the surrounding environment. It use a pair of pyroelectric sensors to detect heat energy in the surrounding environment. These two sensors sit beside each other, and when the signal differential between the two sensors changes (if a person enters the room, for example), the sensor will engage. The PIR sensor can have range from 0.25m to 150m.

Application of PIR Sensor.

These are used to detect motions, it can be used for theft detection, pedestrian detection, etc.

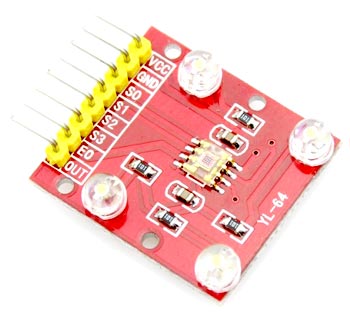

Color Sensor

A color sensor is used to detects the color of a material. it emit a light on an object and detects the reflected light to measure the intensity of red, blue and green light reflecting back from the sensor. These sensors are also equipped with filters to reject the unwanted IR light and UV light. An image of TSC3200 which is extensively used by enthusiast in diy projects is shown below.

Color Sensor Types

There are 2 types of color sensor, 1 emits Red, Blue and Green lights independently and measures the intensity of each light while the other type of sensor emits the broad spectrum of light and detects the light falling onto it. TCS3200 is a commonly used sensor working on the broad spectrum of light method.

The color is detected by presence or absence of either of the light based on the table below:

Application of Color Sensor

Color sensors are commonly used in automobile industry, textile industry and and other manufacturing industries to detect the color of the product. It is also used in cameras to detect the surrounding color to adjust the lighting conditions.

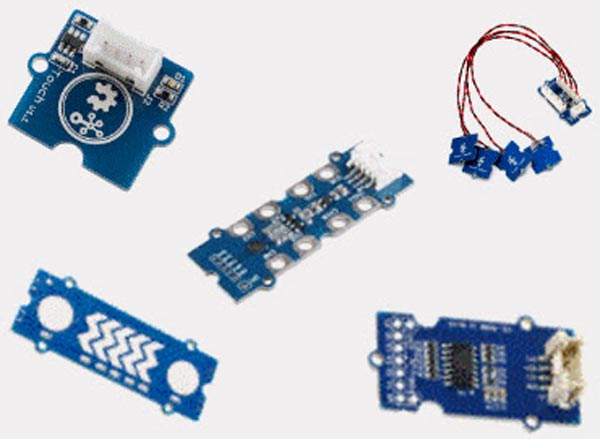

Touch Sensor

Touch sensors also known as tactile sensors are used for detecting or recording physical touch. They work by either allowing or changing the flow of current in the circuit. These sensors are widely used as switches or are embedded in displays to make displays register a command.

Types of Touch Sensors

There are different types of touch sensors such as resistive touch sensor, capacitive touch sensors, Infrared touch sensor, surface acoustic touch sensor etc. The most common types are resistive and capacitive touch sensors which are described below:

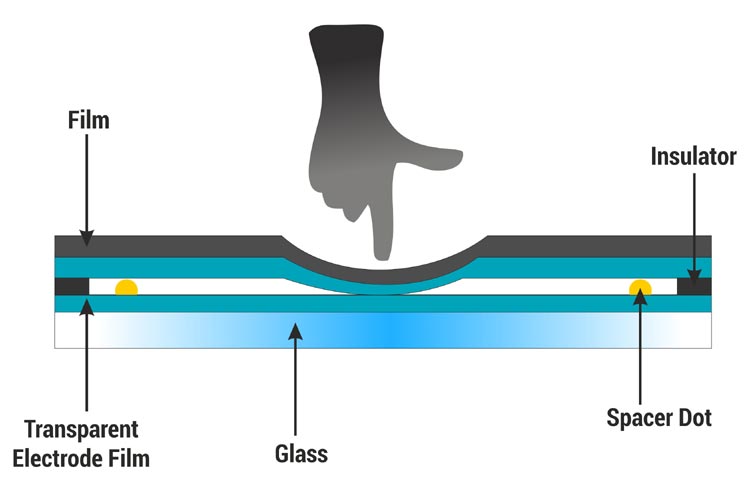

Resistive Touch Screen

Resistive touch sensors are the simplest sensors which have 2 layers of electrically resistive sheets, separated by a layer of inert gas or air. The pressure from touch results both the sheets come in contact with each other thus causing the voltage to change which is interpreted by a circuit. These are mostly found in early smartphones and other touch panels such as touch music instruments and touch cable handheld devices.

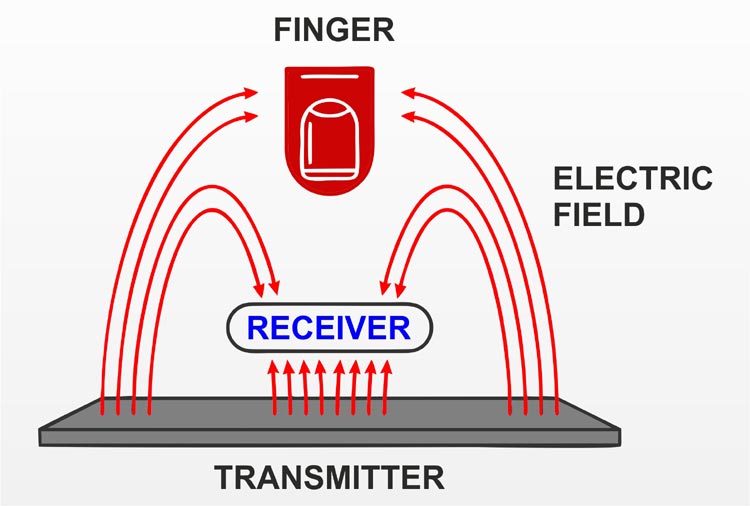

Capacitive Touch Screen

Similar to resistive touch screen, these touch screens have 2 layers of conductors with an insulator between them. The whole setup acts as a capacitor, when our finger which acts likes a conductor comes in contact with the sensor, the capacitance of the point increases. A capacitance measuring circuit continuously measures the capacitance and when it observes the change in capacitance, it generates a signal. These touch sensors are most commonly used in latest smartphones. These are used in smartphones, electronic watches, game consoles, industrial control equipment, touch pads, etc.

Application of Touch sensors

Touch sensors are used as switches in homes, commercial buildings, automobiles, etc. These are embedded into displays of portable devices such as phones, TV screen or other handheld devices.

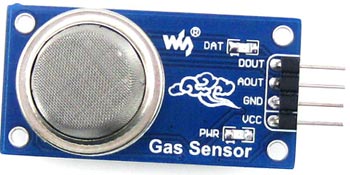

Gas and Chemical Sensors

These sensors are used to detect the presence of different types of gasses and their concentration present in the atmosphere. They are commonly used to detect toxic or explosive gasses and measure gas concentration by changing the resistance value. Detailed explanation on gas sensor can be found here. MQ2 gas sensor is widely used for detecting methane, butane, LPG and smoke.

Different Types of Gas sensors

Gas sensors are typically classified into various types based on the type of the sensing element it is built with. Below is the classification of the various types of gas sensors based on the sensing element that are generally used in various applications:

- Metal Oxide based gas Sensor.

- Optical gas Sensor.

- Electrochemical gas Sensor.

- Capacitance-based gas Sensor.

- Calorimetric gas Sensor.

- Acoustic based gas Sensor.

Application of Gas Sensors

Gas sensors are employed in factories and manufacturing facilities to identify gas leaks, and to detect smoke and carbon monoxide in homes.

Humidity Sensor

Humidity sensor also known as a hygrometer is a sensor used for measuring humidity in air. It senses and measures both moisture and air temperature. The ratio of moisture in the air to the highest amount of moisture at a particular air temperature is called relative humidity. Humidity sensors work by detecting changes that alter electrical currents or temperature in the air. DHT11 is a commonly used humidity sensor

Types of Humidity Sensor

- Capacitive

- Resistive

- Thermal

Application of a Humidity sensor

Used for measuring humidity in homes, offices, granaries, manufacturing plant, storage rooms, humidors, museums, industrial spaces and greenhouses and are also used in meteorology stations to report and predict the weather.

Radiation Detectors

Radiation sensors measures the amount of radiation emitted from a body. There are different sensors which can be used to measure different kinds of radiations such as nuclear, electromagnetic and light. The different particles that can be measured are Alpha particles, Beta particles, Neutrons, X-rays and Gamma rays. The low-cost detectors have a gas-filled tube with a wire at very high voltage which is used for collecting the ionization produced by the incident radiation. But this method is unable to distinguished between different kind of radiation.

The most common types of Radiation Detectors are:

- Gas-filled radiation detectors

- Scintillation radiation detectors

- Solid-state radiation detectors

Application of a Radiation Detector

These sensors can be used to measure radiation from a body in nuclear power plant or to see if an area is safe or not.

Conclusion

A sensor is capable of detecting physical change in our surroundings. Many sensors are capable of giving multiple data, and thus can be used in multiple application. A capacitive sensor can be used as a touch sensor or be used for object detection or position detection, etc. Different accuracy and resolution of sensors are required for different applications and selection of sensor is usually based on the desired accuracy, speed and resolution of data.