1555F Series enclosures have several innovative features that provide excellent functionality

What are the Commonly Available Types of Soldering Iron Tips and Which One Should You Choose?

While soldering might be considered an easy job, people with considerable soldering experience will tell you that each ‘type’ of soldering job is different and that a single soldering iron will not suffice for every job. More specifically, the type of soldering iron tip used for the job determines how easy a particular soldering job is, and to a lesser extent, the quality of the final product.

The most important thing to keep in mind is that the type of tip directly determines the amount of heat transferred to a joint, and care must be taken to ensure that the right tip is used for the right application in order to prevent damaging sensitive components and at the same time transferring enough heat to complete large joints.

In this article, we will discuss the different types of soldering tips to give you an idea of which one might be the right choice for you. Again, make sure to select the tip also based on the soldering iron you have, if you are not sure what type of soldering iron you have or how to choose one, consider reading our article on 'Types of Soldering Iron and How to Select the Right One'.

Types Of Soldering Iron Tips And Their Applications

Soldering iron tips come in three variations:

1. Conical

As the name suggests, this kind of tip features a conical taper with a rounded end. Conical tips deliver heat to a small defined area.

They are good for beginners and for fine work such as SMD soldering. Tips with different ‘sharpnesses’ are available for different jobs, with fine tips being available for SMD soldering and larger tips being used for things like connecting wires to pads.

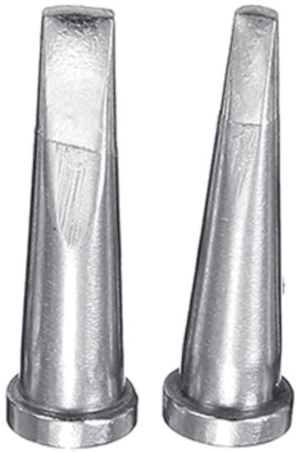

2. Beveled

A beveled soldering iron tip is similar to a conical iron tip, but two ends are flattened to resemble a chisel. This kind of tip is easier to wet since the two flat sides can hold more solder compared to a conical tip.

This feature makes them more versatile compared to conical tips, the fine end makes them useful for fine work like SMD soldering, and the flat ends can be used to transfer a lot of heat to more challenging joints. It is because of their versatility that they are recommended for everyday use.

3. Chisel

Chisel tips are like beveled tips but with only one side flattened. This makes them a reasonable substitute for beveled tips.

Since they have a large surface area compared to other kinds of tips, they are well suited to soldering wires to large pads or tinning a large ground plane which requires a lot of heat transfer. This kind of tip also helps with desoldering because of the large surface area.

Other Specialized Soldering Iron Tips

- Knife tip

This kind of tip is mainly used for applications like drag soldering, where the tip is pre-tinned and dragged across a large row of small SMD pads to solder them at once.

- Bent tip

This type of tip finds use in niche applications for hard-to-reach joints.

Conclusion

For most everyday soldering, a fine beveled tip is ideal. It is also good to have a chisel tip for large jobs that require a lot of heat transfer.